Enhancing Safety in Mining Vehicles with Cubic In-Cabin NDIR CO2 Sensors

In the mining industry, mining vehicles are pivotal for efficient production, serving as essential transportation tools that are operated by mining workers to carry minerals from extraction sites to processing plants or storage areas. However, operators in the confined environment of a vehicle cabin for extended periods will can be affected by the rising CO2 levels and decreasing air quality, which may adversely affect the health of operators.

To address the air quality within operator enclosures of both mobile and stationary mining equipment, the International Organization for Standardization (ISO) established ISO 23875, titled Mining — Air quality control systems for operator enclosures — Performance requirements and test methods. Adherence to the requirements and testing methods set out in the standard supports the safety of machine operators during mining operations.

According to ISO 23875, the air quality control system in mining vehicles should meet specific performance requirements, including maintaining CO2 levels.

As specified in ISO 23875 clause 4.3.3 a), it require that:

1) Shall be set to 1 000 ppm by the manufacturer of the monitoring device. At the factory threshold limit sensor accuracy is /-3%.

2) Sensor accuracy is /- 3% for readings ≥1 000 ppm.

3) For sensor readings <1 000 ppm sensor accuracy is /- 30 ppm or /- 3% whichever is greater.

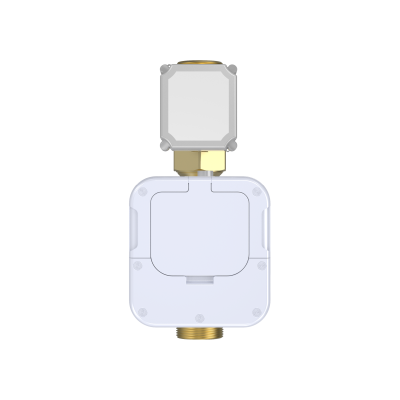

In recognition of the requirements outlined in the standard, Cubic, a leading manufacturer of gas sensors and gas analyzers, has developed high accuracy CO2 sensor based on NDIR technology, ACDS-1001, which could meet the need for vehicle air quality control management during mining operation.

The remarkable features of Cubic automotive CO2 sensor ACDS-1001:

· NDIR (non-dispersive infrared) technology

· High accuracy of 3% of readings for whole measurement and temperature range

· Fast response

· No cross interference, stable performance

· Low power consumption

Cubic automotive NDIR CO2 sensor is designed to continuously monitor the CO2 concentration within the cabin. When CO2 levels approach the critical limit of 1,000 ppm, the CO2 sensor automatically trigger the ventilation system to introduce fresh air and expel air with high CO2 levels, thus maintaining air quality within safe limits and ensuring a safe breathing environment for the operators.

As a highly accurate and fast response NDIR CO2 sensor, ACDS-1001 is an excellent choice for monitoring cabin air quality to achieve cleaner and safer vehicle operation in mining industry.

For more product information, please click on https://en.gassensor.com.cn/CO2Sensor/info_itemid_1320.html or contact: sales@gassensor.com.cn.

Recently Posted

-

Natural Gas Metering Solutions

May 23, 2025Gas metering is essential for quantifying the volume of natural gas in energy sector, especially for flaring process. Accurate mea Read More

Read More -

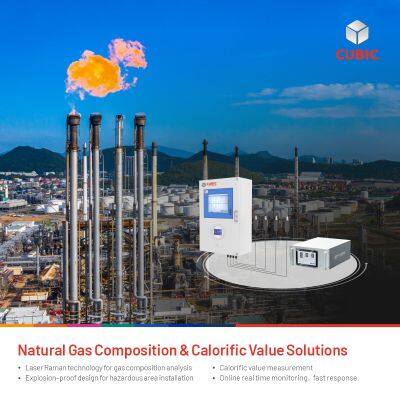

Natural Gas Composition & Calorific Value Solutions

May 23, 2025Following EU methane regulations, it also emphasize the importance of flare combustion efficiency. For instance, Article 17 m Read More

Read More -

Cubic Advanced Sensor Technology for Wall-Mounted Ventilators Enhances Indoor Air Quality

May 22, 2025In the context of modern residential building design, there is an increasing focus on improving indoor air quality (IAQ). Pollutan Read More

Read More -

Methane Emission Monitoring & Quantification Solutions

May 22, 2025Dedicated to the provision of efficient methane emissions solutions in energy sector, Cubic has developed a series of hi Read More

Read More